Retail is no longer only about product availability. It’s about timing, location, and prediction. In 2025, customers expect the right item to be available when they want it and where they want it. Delays, overstocks, and missed opportunities are no longer acceptable.

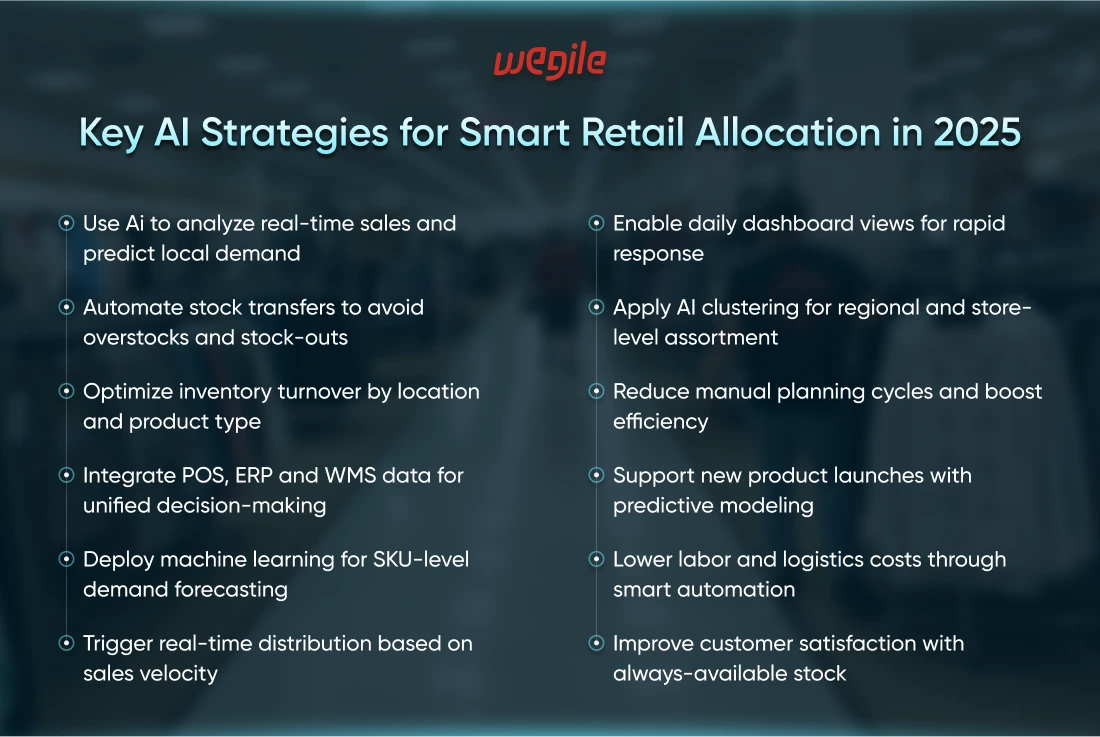

To meet these expectations, retailers are turning to artificial intelligence, not as a trend but as an operational core. AI in retail is being used to improve everything from product forecasting to fulfillment timing. The biggest impact comes from smart allocation and real-time product distribution, where data becomes the driver behind movement, not guesswork.

Retailers who understand and implement AI-driven systems are seeing measurable improvements in turnover rates, inventory accuracy, and customer satisfaction. Let us learn more about the vitality of AI in retail:

Smart allocation refers to using data and algorithms to decide where, when, and how much stock should be sent across a retail network. This includes stores, fulfillment centers, and dark warehouses. Instead of making decisions based on seasonal intuition or fixed rules, AI enables real-time evaluation of demand signals, sales trends, and geographic performance.

Most legacy systems use static historical data and forecast in weekly cycles. They cannot adjust mid-season or during promotions. As a result, one store ends up overstocked while another runs out.

Here are signs your allocation strategy needs AI:

Inventory sits too long in low-performing locations.

Reallocation decisions take too much manual effort.

Stockouts occur despite good supply at nearby stores.

In-store demand fluctuates more often than the system can react.

AI solves this through learning models that identify patterns in real time.

An AI model ingests live sales data, seasonal trends, regional behavior, and external factors like weather or local events. It then recommends what units to send, hold, or transfer. The model gets smarter with every cycle.

Higher inventory turnover in both high- and mid-tier stores.

Lower carrying costs due to reduced overstock and dead inventory.

Better margin protection through timely transfers instead of markdowns.

Store teams can focus on customer service instead of logistics decisions.

AI does not replace human insight. It augments it with faster, broader, and bias-free data processing.

Traditional product distribution is reactive. Orders are fulfilled when inventory hits reorder points or when stores request replenishment. This causes delay, especially when customer demand spikes unexpectedly.

Real-time distribution uses AI models to trigger movement before shortages occur. The system identifies patterns across regions, products, and customer segments, pushing the right products to the right locations without waiting for stockouts.

A real-time distribution engine continuously scans sales velocity, inventory levels, and product affinity. It simulates different scenarios and executes transfers or reorders before human teams notice a shortage.

This engine is not isolated. It integrates with ERP, WMS, and POS data to maintain flow and accuracy across channels.

Retailers now manage hybrid supply chains with physical stores, micro-fulfillment centers, and online orders. No human team can coordinate all variables: warehouse space, customer demand, shipping cost, and seasonal behavior without help.

AI in retail addresses this complexity through scalable automation. Once trained, the models monitor thousands of SKUs across locations and shift inventory faster than any rule-based system.

Agriculture is undergoing a massive change with AI and ML solutions. These aim at increasing yield and reducing costs in following ways:

Flash sale inventory reallocation across regions.

New product launches with no historical demand.

Retail media campaigns driving unpredicted local demand.

Store openings or closings requiring rebalancing stock.

These cases require fast action. Waiting for weekly reviews leads to missed revenue.

Before AI can enhance allocation or distribution, your business must lay a stable data foundation. Most AI models fail not due to algorithms, but because the underlying data lacks structure or accuracy.

Consolidate data from POS, ERP, and warehouse systems.

Clean inconsistencies in SKU naming, unit conversions, and regional tags.

Time-stamp all data to allow historical modeling and trend extraction.

Track lead times between hubs and stores by actual travel, not estimates.

Measure sell-through rates at the daily level.

Log customer returns and restocking delays.

AI models need to learn from behavior, not from ideal flowcharts.

To power smart allocation and real-time product distribution, retailers need more than just basic automation. Sophisticated AI tools enable predictive decision-making, demand sensing, and multi-variable analysis in ways traditional systems cannot handle.

Rather than relying on last year’s numbers, machine learning models examine hundreds of influencing factors. These include location-specific trends, recent promotional activities, pricing changes, and even weather.

Predicts SKU-level demand by region and day.

Learns from returns and refunds to fine-tune future stock allocation.

Continuously retrains based on new inputs from POS systems.

Reinforcement models test multiple scenarios and adjust stock levels based on reward signals like conversion rates, delivery time, or lost sale penalties.

Suggests stock movement strategies between warehouses and stores.

Adapts to changing constraints like truck capacity or labor shortages.

Balances inventory between digital and physical sales channels.

Grouping stores by customer profile, purchase behavior, and product affinity allows the system to allocate more precisely.

Helps avoid overstocking stores that sell fewer seasonal items.

Enables regional variation in assortment planning.

Personalizes stock delivery based on local patterns.

When layered together, these models build a dynamic system where stock flows meet real-world complexity without constant human supervision.

Introducing AI into your retail allocation and distribution process requires alignment between data systems, business goals, and operational structure. It is not a quick integration. It is a structured rollout.

Here’s how to start:

Understand how allocation decisions are currently made. Identify gaps in timing, accuracy, and flexibility. List systems involved and key failure points like manual overrides or outdated forecasts.

Bring inventory, sales, logistics, and promotional data into one source. Data must be real-time, labeled correctly, and historically rich. Without this, AI models will generate poor outputs.

Select a limited test case, such as allocation of high-margin products across 10 stores. Test AI recommendations, compare against traditional decisions, and track sales results.

While the system makes suggestions, retail teams must know how the model arrived at those results. Provide dashboards that offer transparency, not just outputs.

As confidence grows, scale to more product categories, locations, and distribution actions. Build feedback loops into the model using real-world sales and fulfillment outcomes.

AI adoption in retail is most successful when it starts small, proves value, and scales strategically.

The most advanced AI models fail without operational alignment. Teams must shift how they view inventory, location strategy, and planning cycles. That requires structural readiness.

AI works in real time. If your teams only review stock once per month, they will miss the value. Move toward daily dashboards and quick-response teams.

Create roles like AI Product Owner or Data Strategy Lead. These individuals bridge tech and merchandising, making sure the system is usable and accurate.

AI systems depend on collaboration. Data teams must share insight with store ops. Planners must communicate promotions in advance. Merchandisers must tag inventory properly.

This cross-functional alignment turns AI from a background tool into a core business function.

AI is not an abstract improvement. It delivers measurable business value that compounds with scale.

Here are outcomes retailers report after successful adoption:

Inventory turnover improves by 15 to 25 percent in optimized locations.

Stockouts decrease without requiring large inventory buffers.

Markdowns drop due to better mid-season allocation decisions.

Labor cost savings from fewer manual planning cycles and reactive shipping.

Customer satisfaction increases when availability is consistent across channels.

AI lets businesses operate leaner while delivering more. That creates a dual advantage of margin protection and loyalty building.

Retailers that still depend on manual planning or basic rules are already behind. Customers shop across devices, expect fast fulfillment, and rarely forgive missed expectations. Smart allocation and real-time product distribution have moved from luxury to necessity.

AI makes this shift not only possible but profitable. When implemented correctly, it becomes the difference between reacting to demand and staying ahead of it.

To build this kind of system, you need not just tools, but the right partner who understands both your business logic and technology needs.

Implementing AI in retail requires more than code. It demands a deep understanding of retail flow, SKU dynamics, and operational nuance. That’s where Wegile stands out.

As an experienced AI app development company, Wegile builds custom AI-driven systems for smart allocation, real-time distribution, and inventory intelligence. From data modeling to mobile app development, Wegile helps you move beyond reactive planning and toward automated optimization.

Ready to bring AI into your retail ecosystem? Build with Wegile, the AI app development company trusted by future-ready businesses.