Imagine a supply chain that runs smoothly without delays or interruptions. Sounds like a fantasy, right? That dream is now possible with generative AI. Gen AI is a revolutionary tool in the supply chain. This cutting-edge technology is changing the domain by accurately anticipating demand, optimizing routes, and managing inventory. It’s like having a crystal ball that can predict and shape the future. What if you could cut expenses, boost customer satisfaction, and strengthen your supply chain at the same? Yes, with generative AI, it’s possible! To keep ahead of the competition, top organizations use this secret tool. The best part? Implementing it is simpler than you think. Want to explore how generative AI can transform your business? Let’s explore how this technology is changing the present and future of supply chain management.

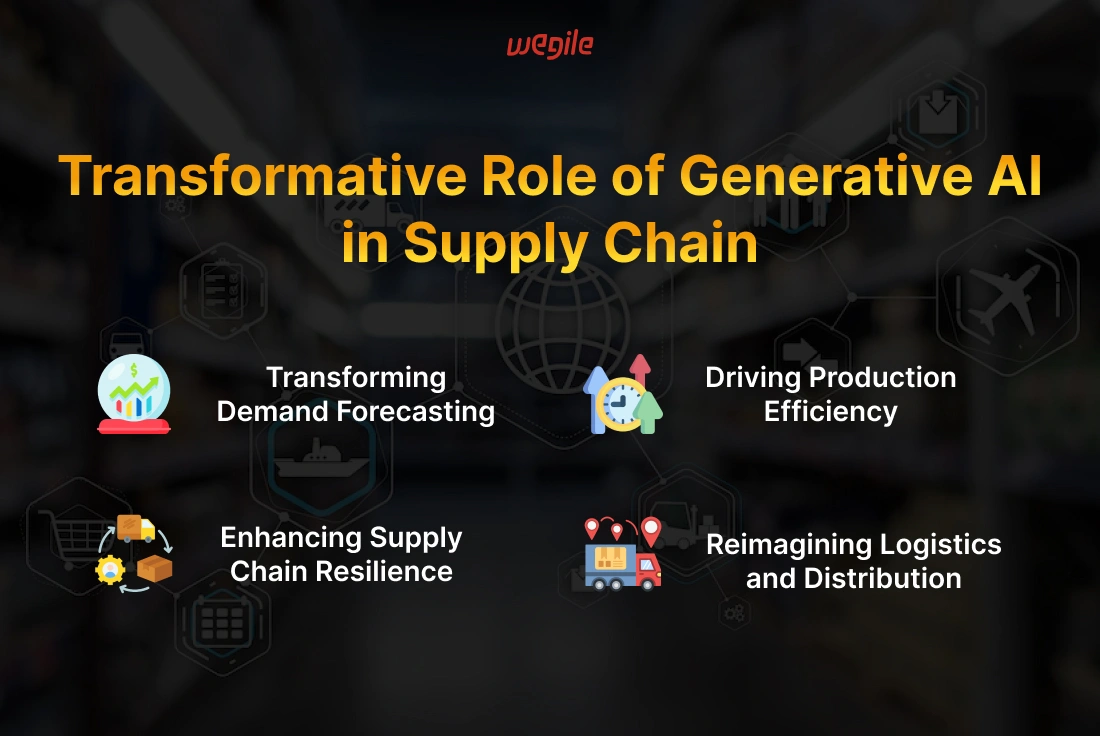

Generative AI is becoming crucial in the supply chain. As global supply chains become increasingly complicated, smarter, faster, and more adaptive solutions are needed. Generative AI improves production-to-delivery processes. It offers capabilities that traditional approaches cannot match. Supply chains are increasingly using generative AI because it can efficiently process and analyze enormous amounts of data in real-time. It helps organizations avoid mistakes, estimate demand, and respond rapidly to disruptions. AI can transform reactive supply networks into proactive or predictive ones. This helps companies remain ahead. Further, generative AI adds flexibility and innovation. It can simulate various scenarios. This lets companies test strategies before implementing them. Further, it reduces risk and advances progress. Thus, Generative AI is transforming the supply chain and not just solely improving it.

Must Read: What Every CEO Must Know About Generative AI?

The heart of any supply chain is demand forecasting. Get it wrong, and you have surplus inventory or unfulfilled customer demand. Both scenarios can be costly if wrong practices are followed. Generative AI analyzes massive datasets to improve prediction accuracy. It can analyze past sales, market trends, consumer behavior, economic data, and social media sentiment. AI, based on the same information, delivers precise demand forecasts to assist firms in planning inventories, production, and logistics. This reduces inventory shortages or overstock and also optimizes resource allocation. The result? A more flexible supply chain that responds instantly to market changes.

Supply chain agility is more important than ever in times of uncertainty. Generative AI is crucial to resiliency. It suggests flexible risk minimization strategies. AI also predicts disruptions utilizing numerous data sources. For example, natural calamities, geopolitical tensions, and consumer behavior can cause interruptions. AI helps firms anticipate risks, create backup plans, and make informed decisions before a crisis. Additionally, AI-driven simulations can model scenario impacts. This lets companies test and improve resilience strategies. Thus, Generative AI improves supply chains beyond efficiency. They become resilient, flexible systems that can weather uncertainty.

Must Read: What is the Difference between Generative AI and AI?A successful supply chain performance depends on efficiency. Here, generative AI is driving it to new heights. This is particularly true in production. AI boosts production speed, cost, and efficiency. AI is excellent at waste reduction, production schedule optimization, and production improvement. Generational AI can discover manufacturing bottlenecks, inefficiencies, and resource underutilization. It can then recommend output-maximizing manufacturing schedules. This reduces downtime and resource use. AI-driven quality control systems can additionally identify problems in real-time. So only high-quality goods are made. Thus, generative AI is vital for fine-tuning manufacturing processes to increase production and reduce costs.

Distribution and logistics are often the most challenging parts of the supply chain. It involves numerous variables like traffic, weather, and delivery windows. These procedures are changing with generative AI. It improves routes, enables live tracking, and prepares for self-driving delivery. AI algorithms can optimize routes based on traffic, weather, and delivery schedules. This saves fuel, speeds delivery, and improves customer happiness. Further, AI-powered real-time tracking lets businesses and customers track shipments throughout. This increases trust and transparency. Soon, AI-driven driverless cars and drones may dominate logistics. This will further change the pattern of delivering goods.

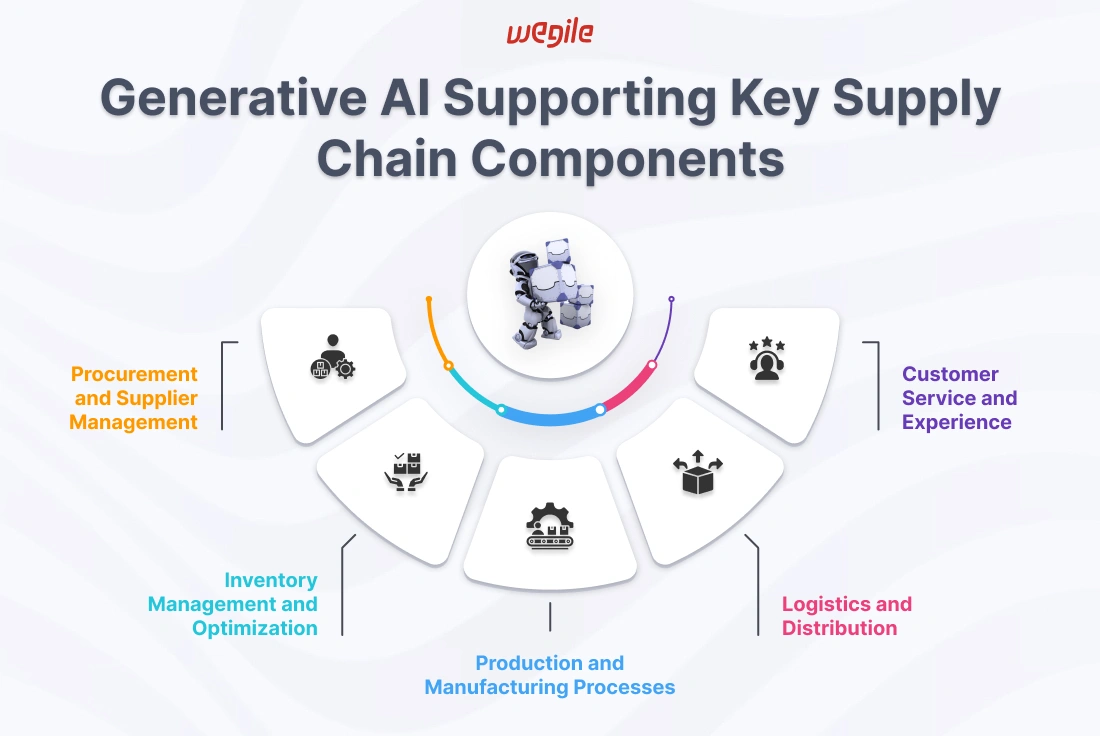

The modern supply chain goes beyond production to delivery. A company’s success depends on a complex web of interconnected activities. Advanced Generative AI makes these processes more efficient, durable, and flexible. Let’s see how generative AI improves each supply chain component.

Every supply chain needs procurement and supplier management. Supplier selection, terms, and risk management are essential for successful operations. Here, generative AI is crucial. Its ability to analyze big datasets helps companies find trusted suppliers, predict interruptions, and negotiate better contracts. For example, historical data and market and geopolitical circumstances can help AI predict supplier performance. Forecasting helps companies make smarter decisions and prevent supply chain interruptions. Moreover, AI-driven persuasion tools can simulate situations to help procurement teams negotiate better bargains and reduce risk.

Inventory management requires balance. Avoiding surplus and shortages is crucial. Businesses’ inventory management is changing with generative AI. It offers predictive analytics and real-time insights. AI algorithms can assess demand patterns based on seasonality, promotions, and social media trends. Moreover, businesses can optimize inventory levels, cut holding costs, and guarantee customers have products when they need them. AI can also recommend reorder points and quantities to avoid overstocking or understocking.

Must Read: How Generative AI Can Be Used in the Real World?Production and manufacturing highly prioritize quality and efficiency. These methods benefit greatly from generative AI. It improves automation, production scheduling, and quality control. AI also simulates several production situations. It helps manufacturers find efficient procedures and save downtime. AI can detect machine breakdowns and enable proactive maintenance, eliminating costly interruptions. AI-powered quality control systems are vital. It detects faults better than humans to ensure only the best products reach the market.

Logistics and distribution are the lifelines of the supply chain. They’re about delivering things on time and in perfect condition. Generative AI improves this component. It optimizes routing, fleet management, and warehousing operations. AI systems also assess traffic, weather, and delivery windows. It determines the most efficient transit routes. The outcome is lower gasoline expenses, faster delivery, and happier customers. Businesses can automate warehouse picking and packing with AI-powered robots. These technologies generally eliminate errors and speed up order fulfillment. Moreover, AI can also manage warehouse inventory allocation to make high-demand commodities accessible.

Customer service is essential in the current competitive environment. Here, Generative AI supports businesses by improving interaction with clients. It offers personalized experiences, faster response times, and purchase journey support. AI-powered chatbots and virtual assistants can accept client requests 24/7. They give immediate support and free up agents to handle more complex concerns. AI systems can additionally suggest products and improve customer experiences using their data. Further, AI can predict and resolve post-purchase issues. This guarantees loyalty and satisfaction.

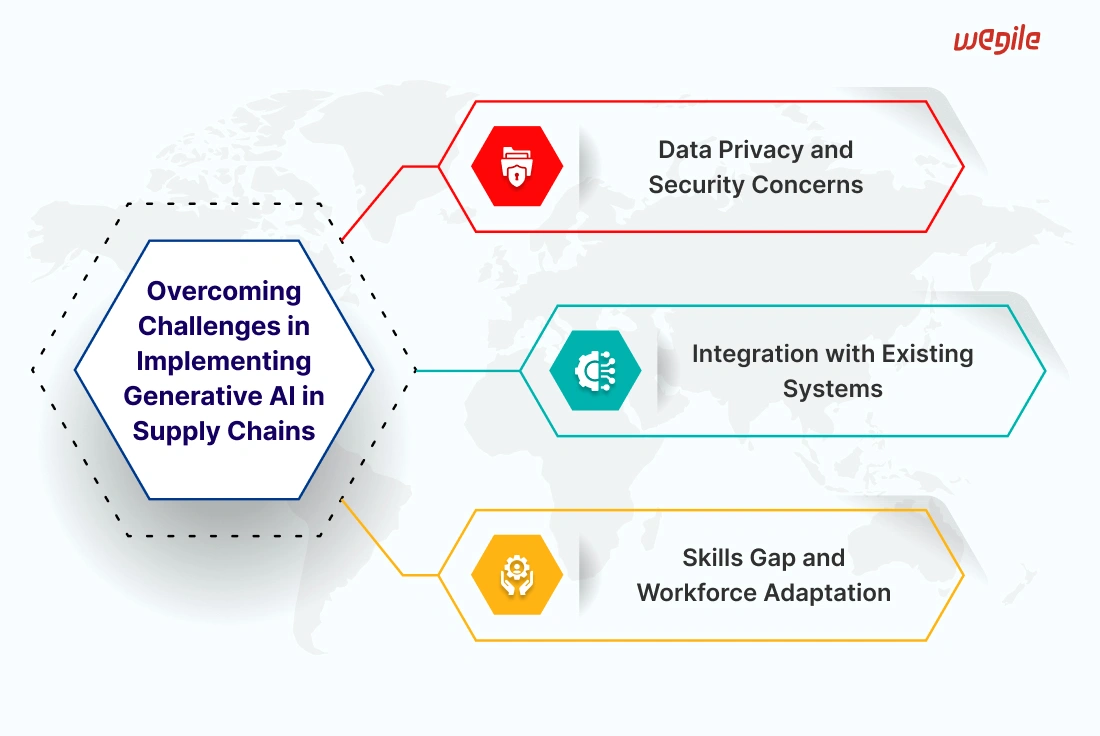

Generative AI in supply chains seems like an abstract concept due to its transformative capabilities. Yet, like any great tool, generative AI has drawbacks. Let’s examine these potential obstacles and how firms might overcome them to maximize AI in supply chains.

Data is a treasure in the digital era. But with great power comes responsibility, especially when handling sensitive supply chain data. When given more data, generative AI performs better. However, this data dependence presents severe privacy and security problems. Businesses must safeguard their data from breaches, leaks, and unwanted access. Strong encryption algorithms protect data at rest and in transit. Companies should additionally invest in security assessments and updates to stay ahead of threats. Further, transparency with stakeholders regarding data collection, storage, and use builds trust in AI-driven operations.

Adding generative AI to a well-established supply chain may seem like attempting to fit a square peg into a round hole. However, older systems may not be compatible with modern AI technologies. This causes inefficiencies. Businesses need to address this issue. Start by selecting the most important areas where AI can immediately add value and integrate it into these systems. Use middleware or APIs to connect legacy systems to new AI platforms. Early involvement of IT and operational teams assures they are ready for technological difficulties and can provide significant insights for faster integration.

Must Read: Top Generative AI Solutions: Scaling & Best PracticesThe new approach of working with generative AI can be thrilling yet intimidating for the workforce. AI in supply chains involves new abilities and task changes. This may leave the workforce unprepared for AI-driven procedures as they don’t possess enough skills. So what’s the solution here? Reskilling and upskilling. Company training programs should teach staff how to operate with AI. This could involve workshops, online courses, or educational institution partnerships. Fostering a culture of continuous learning encourages people to embrace new technologies and perceive AI as a tool to enhance their responsibilities, not replace them. This way, businesses can maximize productivity and ease the transition to AI-driven workflows by supporting the workforce.

As we look ahead, the role of generative AI in supply chain management is set to grow even more transformative. The future holds exciting possibilities as AI continues to integrate with other cutting-edge technologies, drive sustainability, and become a key player in long-term strategic planning. Let’s explore what the future might look like.

Generative AI is powerful alone, but when combined with IoT, blockchain, and robotics, the possibilities are unlimited. Envision a supply chain where IoT connects every device, machine, and component, feeding AI systems real-time data. This would enable unparalleled automation, efficiency, and response. IoT sensors can track inventory levels in real-time, while AI predicts supply needs. Blockchain’s secure and transparent ledger system might interact with AI to record and verify every supply chain transaction and movement, minimizing fraud and errors. Further, AI-powered robotics might manage assembly lines and warehouses with precision and speed that humans cannot match. Thus, the combination of these technologies will produce a supply chain that is predictive, adaptive, and able to respond to changes and disruptions faster than ever.

Sustainability is not just a concept; it’s essential. Sustainable supply chain practices benefit from generative AI. Artificial Intelligence can help firms reduce their environmental effect by optimizing routes, waste, and resource management. It can further recommend fuel-efficient routes or find ways to reuse or recycle items. This will result in a reduction of emissions and waste. However, firms must address ethical issues as AI becomes increasingly prevalent in supply chains. This involves ensuring that AI-driven decisions refrain from harming vulnerable groups like developing country suppliers or displacing workers without proper support. Companies must use transparent, fair, and ethical AI approaches to preserve trust and social responsibility.

Must Read: How to Build Generative AI Apps: A Comprehensive GuideThe future is more about surviving rather than just thriving. Companies that wish to stay ahead must incorporate generative AI into their long-term strategy. Think further over immediate benefits and evaluate how AI might assist growth and innovation over the next decade and into the future. Long-term AI planning involves identifying areas where AI can generate ongoing development, such as predictive analytics for market trends or new business models based on AI insights. It also requires training and development initiatives to prepare workers for an AI-powered future. Companies must also invest in AI-supporting infrastructure and systems to build a solid, flexible, and scalable technology stack. By doing so, they may position themselves to fully leverage AI, converting obstacles into opportunities and ensuring long-term success.

Generative AI in the supply chain isn’t a passing trend as we conclude our tour. It is here to stay and is already causing industry waves. While the rewards are huge, generative AI can feel like entering the unknown. The good news? You don’t have to face this new landscape alone. Generative AI solutions can fit smoothly into your supply chain processes, improving efficiency and lowering costs. However, implementing these tools effectively requires a proper partner.

At this point, you might be wondering how to get started or even how to scale your existing AI initiatives. That’s where Wegile comes in. Our custom generative AI app development services can help you maximize this technology for your organization. We can help you streamline your supply chain, improve forecasting, or beat the competition. Together, we can make your supply chain a competitive advantage that fosters growth and success. Ready to get started? The future of supply chain management is here, and it’s powered by generative AI.

Browse Our Services

Browse Our Services